AS-Motor tyre sealant: Mow without flats

A flat tyre when mowing frustratingly results in lost time. AS-Motor now offers a solution with “Flat-Stop” tyre sealant, which seals punctures before the operator notices. This ecologically harmless product has no expiry date and comes with antifreeze and corrosion protection.

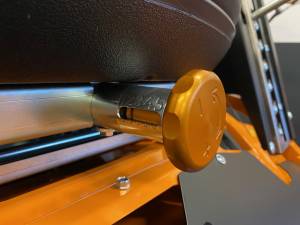

Using AS-Motor tyre sealant is quite simple: Let air out of the tyre or inner-tube and fill “Flat-Stop” through the valve. That’s it. The product has an unlimited shelf life and does not stick or clump. Once filled, the liquid rotates along with the tyre. If a puncture occurs up to 15 millimetres in diameter – from objects such as thorns, branches, or nails – the puncture seals on its own. Air pressure forces millions of Kevlar fibres suspended in propylene glycol into the opening, sealing the puncture within two to three wheel revolutions. This happens so quickly that there is virtually no loss of pressure, which in most cases leaves the operator unaware of the fact that a tyre has been punctured.

Suitable for all types of tyres

“Flat-Stop” is suitable for all agricultural and forestry vehicle tyres that do not exceed a speed of 80 kilometres per hour. It is at least 90% effective on the tread of tubeless tyres and at least 75% effective on tubular tyres. An antifreeze component prevents the sealant from freezing at low temperatures and corrosion protection protects the rim.

The product can be purchased from authorised dealers in a 950-milliliter bottle – sufficient to seal the rear tyre of an AS-Motor Sherpa ride-on mower – or in a 20-liter container. Information on how much puncture protection agent must be filled per tyre is provided on AS-Motor’s webpage, under Products/Accessories. Avoid gradual pressure loss, flat tyres and downtimes for years to come with “Flat-Stop.”